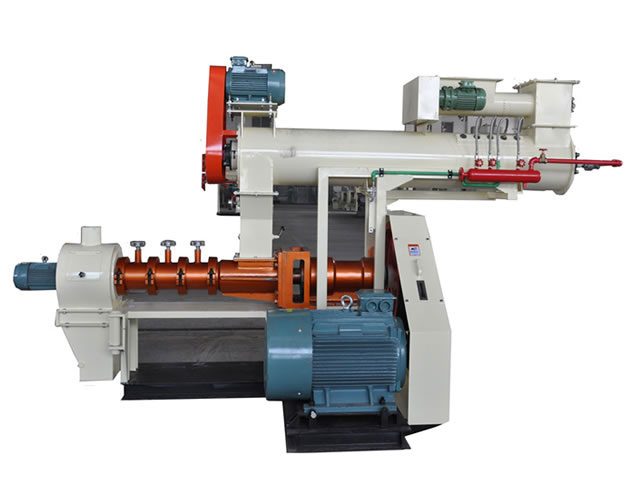

Performance features:

Suiloble for extruding slrking/floating aquafeed,amamental flsh feed and so on,The pelletsize ranges fromΦ0.6to16mm.

Frequency inverter controlled feeder ensures material to be fed everily and constanfly.

Thedouble-shaft differential speed conditioner makes material fully gelatinization by means of mechanical shearing/mixing of steam with material.Retaining time can be up to 120s.

All contacting parts are made of stainless steel.

Screw sleeve adopts jacket construction,which can injected in steam or cooling water;thus the extruding temperature can be controlled effectively.

Steam and water canalsobe directly injected directly into the extruding chamber.

The removable cutting device is equipped with elastic cutting knives that fit surface of die plate tenderly and can be quickly and simply adjusted in six direcfions.The variable-speed motor easily confrol the length of pellets.

Major Technicai Parameters

| Dia of Screw (MM) | Capacity (t/h) | Main motor (KW) | Conditioner (KW) | Feeder (KW) | Knives (KW) | Water Pump (KW) | |

|---|---|---|---|---|---|---|---|

| TLSLP-75 | 75 | 0.1-0.3 | 18.5/22 | 1.1×2 | 0.75 | 0.75 | |

| TLSLP-85 | 85 | 0.3-0.5 | 30/37 | 1.1×2 | 0.75 | 0.75 | |

| TLEX135-55/75 | 135 | 0.6-1.5 | 55/75 | 3 | 0.55 | 3 | 1.1 |

| TLEX165-110/132/160 | 165 | 1.5-4.0 | 110/132/160 | 7.5/11 | 0.75 | 4 | 1.1 |

| TLTS150X2-132 | 150 | 2.0-4.0 | 132 | 15 | 1.5 | 4 | 1.1 |

| TLTS150X2X60 | 150 | 3.0-5.0 | 160 | 18.5 | 1.5 | 4 | 1.1 |